By Tony Dwight

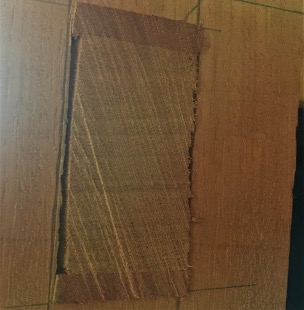

On April 20th we took delivery of a large consignment of timber for the construction of the bespoke workbench, which is needed for the assembly of the 4.5m wide gates. A prearranged area within the depths of the running shed was to be used as our manufacturing facility.

The workbench was not a simple construction as it needed to be perfectly flat (to prevent any warping of the frames) but also to be very robust as the completed individual gates will be very heavy.

We also took delivery of two new machines that were required to ensure the precision of the joints within the frames. These were a morticing machine and a bed planner both of which have been installed into the designated work area and coupled to the new power supplies that we installed along with the temporary overhead lighting.

By the 4th of May the workbench was almost complete but was ready to except the arrival of the Iroko hardwood gate timbers that had been machined by the supplier (Glendale Joinery of Woodston) to the required dimensions we provided.

Alan Scott and Dave Read were now set up for the manufacture of the first gate (D). Each gate is slightly different in widths, so they have been designated A-D with corresponding positions on the existing gates. The progress of the first gate was taken steadily as we couldn’t afford mistakes because the hardwood is not cheap, but by 23rd of May the first frame was complete with the tenon joints fixed by the use of dowels and wedges.

On the 1st of June the cross bracings for the first gate had been made and temporarily fitted as they will need to be removed to have the holes for the steel rods drilled in them.

The steel rods were also delivered on the 1st of June all twenty of them at 6m long, the first five of these rods have been cut to length and threaded at both ends by our colleagues in the main workshop, an example of inter department collaboration at its best.

Alan and Dave have spent a lot of time trying to devise a jig to facilitate the drilling of the cross braces at the angle, required for the insertion of the steel rods, but this has not been successful and after many attempts and various jigs it has been decided that drilling the cross bracings without any jig actually gives more precise results.

With both operatives having a week’s holiday within June, work has concentrated on the manufacture of the other gate frames and as of the 2nd July they have machined and dry fitted the frames for gates A & C which are ready for the drilling and fitting of the dowels and the end wedges.

I will report further progress on this most interesting project in due course.